Brass vs Aluminum Burners: Durability, Maintenance & Longevity

Choosing the right material for your gas stove burner is a key factor that determines its lifespan, maintenance needs, and long-term value. In the kitchen appliance market, the choice often comes down to two popular materials: brass and aluminum.

While aluminum burners offer a budget-friendly option, brass burners are overwhelmingly superior in terms of durability and maintenance, making them the preferred, high-efficiency choice for heavy and regular use.

Here is a detailed comparison of brass versus aluminum gas burners across key metrics:

1. Durability and Resistance to Heat

The longevity of a burner is directly related to its ability to resist the intense heat and daily wear-and-tear of cooking.

Brass Burners: Built for Endurance

Brass, an alloy of copper and zinc, is significantly denser and harder than aluminum. This robust construction provides superior durability:

- Resistance to Warping: Brass has a higher melting point (around 1650∘F−1700∘F), making it highly resistant to warping or deforming under prolonged, intense heat. This means the critical shape of the flame ports remains consistent, preserving the burner’s thermal efficiency over years.

- Corrosion Resistance: Brass naturally resists rust and corrosion, even when exposed to moisture, spilled acidic foods (like vinegar or lemon juice), and common household cleaning agents.

- Heavy Use Ready: Brass easily withstands the weight of heavy cookware and the frequent placement and removal of pots, making it the ideal choice for demanding kitchens.

Aluminum Burners: Prone to Deformation

Aluminum burners are lighter and more cost-effective but sacrifice structural integrity over time:

- Susceptibility to Warping: Aluminum is a softer metal with a lower melting point (∼1220∘F). Prolonged exposure to high flames can cause the burner cap or base to warp or deform.

- Efficiency Loss: Even minor deformation can throw off the critical gas-air mixture, leading to inefficient, yellow flames and increasing LPG consumption.

- Corrosion Vulnerability: Aluminum is more vulnerable to corrosion and oxidation, which can be accelerated by moisture or highly acidic spills. This corrosive wear shortens the burner’s useful life.

2. Heat Properties and Cooking Performance

The material also impacts how quickly the burner heats up and how it transfers that energy to the cooking vessel.

| Feature | Brass Burner | Aluminum Burner |

| Heating Speed | Slower to heat initially, but retains heat longer. | Heats up very quickly, cools quickly. |

| Heat Distribution | Excellent—ensures even heat dispersal across the cooking base. | Quick initial heat, but less effective at retaining and evenly distributing heat. |

| Long-Term Efficiency | Sustained high efficiency due to structural stability. | Efficiency drops over time due to deformation and wear. |

Export to Sheets

For cooking styles that require sustained, even, and consistent heat (common in Indian cooking), the heat-retention properties and stability of brass burners are a distinct advantage.

3. Maintenance and Longevity

The material determines how much effort is required to keep the burner clean and functioning at its peak.

Maintenance of Brass Burners

While brass requires regular cleaning to prevent the build-up of grime that can clog the flame ports, its inherent material strength simplifies long-term maintenance:

- Cleaning: Can be easily scrubbed with standard cleaning solutions without fear of warping.

- Tarnishing: Brass may develop a natural, dark patina (tarnishing) over time, which is purely aesthetic and does not affect performance. It can be polished back to shine if desired.

- Lifespan: With proper care, a high-quality brass burner can last for 10-15 years or more, making the higher initial cost a worthwhile long-term investment.

Maintenance of Aluminum Burners

Aluminum’s softness makes it require more delicate handling, despite its lightweight nature:

- Cleaning: While lightweight and easy to handle, scrubbing too vigorously can scratch the surface, potentially accelerating corrosion.

- Residue: Due to its quicker heating/cooling cycle, food residue can sometimes adhere more stubbornly.

- Replacement Frequency: Aluminum burners will likely require replacement sooner, often due to significant visible wear, pitting from corrosion, or noticeable changes in flame quality (due to warping).

Brass vs. Aluminum Gas Burner FAQs (Durability & Maintenance)

These FAQs thoroughly address consumer concerns about longevity and upkeep, and brass burner durability, aluminum burner warping, thermal efficiency, and burner corrosion resistance.

1. Which type of gas burner is more durable: brass or aluminum?

Brass burners are significantly more durable. They are denser and harder, offering high resistance to mechanical damage and the intense heat of cooking. Aluminum is a softer metal, making it more prone to:

- Warping under high or prolonged heat.

- Corrosion and wear from acidic spills and moisture.

- Reduced lifespan in kitchens with frequent or heavy usage.

2. How does burner material affect thermal efficiency over time?

The material’s durability is crucial for maintaining thermal efficiency.

- Brass: Because it resists warping, the critical shape of the burner cup and the alignment of the flame ports remain consistent for years. This ensures the gas/air mixture is always optimized, sustaining high efficiency.

- Aluminum: When aluminum warps or corrodes, the flame pattern is disrupted. This leads to a less-efficient, often yellow flame that wastes gas and lowers the burner’s long-term efficiency.

3. Are aluminum burners more prone to warping than brass burners?

Yes. Aluminum has a lower melting point (around 1220∘F) compared to brass (around 1650∘F). Aluminum burners are more susceptible to deformation and warping from prolonged exposure to the high temperatures generated during cooking, especially under heavy, thick-bottomed cookware.

4. Do brass burners require less maintenance than aluminum burners?

In terms of functional maintenance and replacement, yes, brass requires less.

- Brass: Highly corrosion-resistant. It requires only regular cleaning to prevent port blockage; the material itself will not rust or pit from general use, ensuring a longer functional life and less frequent replacement.

- Aluminum: Needs more careful, consistent cleaning to prevent corrosion from spills, which can pit the surface and permanently reduce performance. They also need replacement more frequently.

5. Is the tarnishing (darkening) of brass burners a sign of reduced performance?

No, the darkening or developing a patina on a brass burner is purely aesthetic and does not affect performance. Tarnishing is a natural oxidation process. As long as the flame ports are kept clean and open, the burner will retain its original high thermal efficiency and cooking speed.

6. Why do professional chefs or premium appliance manufacturers prefer brass burners?

Premium brands and professionals choose brass due to its:

- Structural Stability: Guarantees that the intended flame pattern and efficiency (e.g., in a high-efficiency SABAF burner) are maintained over many years.

- Heat Retention: Brass is better at retaining heat, contributing to a more even and consistent cooking temperature, which is essential for professional results.

7. Which burner material is the better long-term value for a busy kitchen?

Brass burners are the superior long-term investment. Although they have a higher initial cost, their lifespan is significantly longer (often 10+ years), and their sustained high thermal efficiency translates into lower gas consumption over the life of the appliance, ultimately providing the best value.

Conclusion: The Long-Term Value of Brass

When comparing durability and maintenance, the choice is clear: Brass burners are the superior long-term investment.

While aluminum burners serve well for low-frequency or budget-conscious cooks, brass is essential for heavy or regular use. Its high resistance to heat and corrosion ensures stable performance, maintains thermal efficiency, and guarantees a significantly longer lifespan, providing the best value and fewest headaches over the years.

Gas Stoves: Today’s Top Deals

Faber 2 Burner 70Cm Cooktop |Auto Ignition| |Metal Knobs| MS Diamond coated Pan Support | Matt Black Glass Finish |5 Yrs Warranty On Glass &…

DELTA® Gas Stove Replacement Parts | 92 MM Jumbo Mixing Tube | Jumbo Mixing Tube for Glass Top Gas Stove Pack of 1 Piece

DELTA Gas Stove Replacement Parts | 78 MM 3 Pad Big Mixing Tube | Big Mixing Tube for Glass Top Gas Stove Pack of 1 Piece

DELTA Gas Stove Parts | 68 MM Small + 78 MM Big + 92 MM Jumbo Mixing Tube | Mixing Tube for Glass Top Gas Stove Pack of 3 Pcs

DELTA® Gas Stove Replacement Parts | 68 MM 3 Pad Small Mixing Tube | Small Mixing Tube for Glass Top Gas Stove Pack of 1 Piece

DELTA® Gas Stove Replacement Parts Type 2, Small 68 MM Brass Burner for Manual Ignition Glass Top Gas Stove Pack of 1 Piece

Spark Sell Heavy Duty Stainless Steel Gas Stove 10x10x8 Inch | Commercial Single Burner Cooking Stove | High Pressure LPG Burner | Strong Body for…

Sujata 3 Burner Gas Stove Glass Top | 5 Years Warranty | Auto Ignition Gas Stove 3 Burner, CookTop cum Hob Top 3 Burners, LPG & PNG Compatible,…

Vidiem Gas Stove SS2 196 A Viva (Silver & Black) | 2 Burner Stainless Steel | ISI Certified | Manual Ignition | 5 Years Warranty

Pigeon Twinspark Hob 3 Burner Multi Spark Integrated Auto Ignition With Forged Burners, Scratch Resistant 6 mm Thick Toughened Glass Top For Easy…

Pigeon by Stovekraft Maxima Stainless Steel 2 Burner Gas Stove with Brass Burners, Manual Ignition, standard 12312 (Silver)

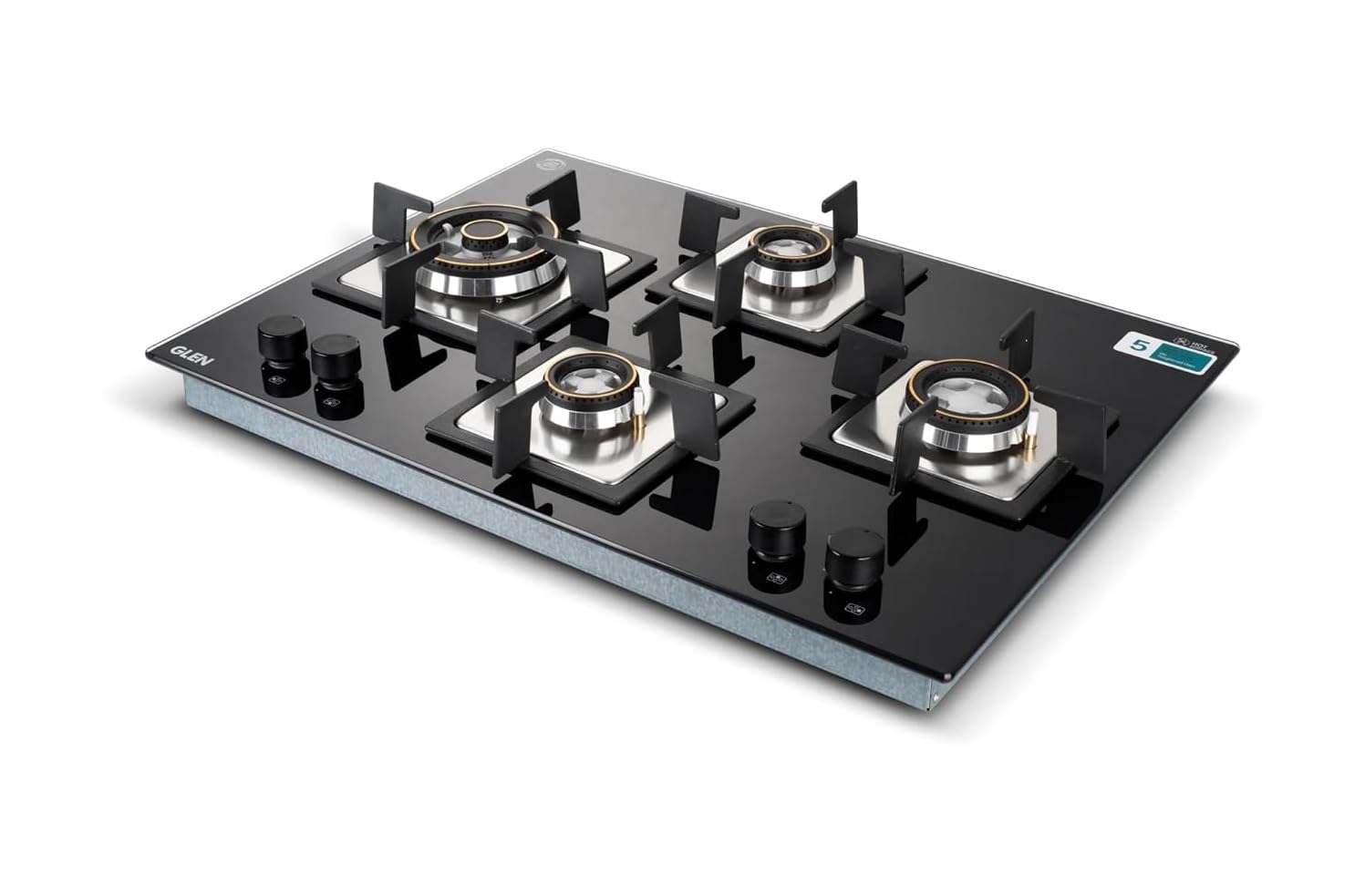

Glen 4 Burner Gas Stove 70 cm Built-In Hob & Hobtop | Auto Ignition | 8mm Toughened Glass Top | Double Ring Forged Brass Burners | LPG Compatible |…

Elica 70cm 4 Burner Auto Ignition Hob | RG FLEXI 470 LOTUS IND HD BRASS | SABAF Brass Burners | Built-in & Freestanding | Toughened Black Glass |…

Elica 90cm 5 Burner Auto Ignition Hob | RG FLEXI 590 LOTUS IND HD Brass | SABAF Brass Burners | Built-in & Freestanding | Toughened Black Glass |…

Elica Hob 3 Burner Auto Ignition Glass Top – 1 Double Ring Brass Burner and 2 Mini Triple Ring Brass Burner Gas Stove (CLASSIC FLEXI AB HCT 3B70…

Elica Hob 3 Burner Auto Ignition Glass Top with Direct Flame Aluminum Brass Burners | Fully Sealed Burner Cups | IND FLEXI AB 375 DX DFS

Elica 3 Burner Stainless Steel Gas Stove (INOX 753 SS), Manual, Silver

Elica Hob 4 Burner Auto Ignition Glass Top – 2 Double Ring Brass Burner and 2 Mini Triple Ring Brass Burner Gas Stove (CLASSIC FLEXI AB HCT 4B70…

Elica Hob 4 Burner Auto Ignition Glass Top – 2 Small and 2 Medium Brass Gas Stove (FLEXI FB HCT 470 DX)

Elica Hob 4 Burner Auto Ignition Glass Top – 2 Double Ring Brass, 1 Dual Brass Burner and 1 Mini Triple Ring Brass Gas Stove (CLASSIC AB MFC 4B 60…

Elica Hob 4 Burner Auto Ignition Glass Top – 3 Double Ring Brass and 1 Mini Triple Ring Brass Burner Gas Stove (CLASSIC AB 4B 60), Black

Elica Hob 4 Burner Auto Ignition Glass Top- 2 Mini Triple Ring And 2 Double Ring Brass Burner (Flexi Pro Fb 4B 70 Mt Dx), Black

Elica Hob 4 Burner Auto Ignition Glass Top – 1 Dual, 1 Medium and 2 Small Full Brass Gas Stove (Classic Flexi FB MFC 4B 70 MT) Black

Elica Vetro 3 Burner Gas Stove (7031 CT VETRO Black) | Toughened Glass Top | High-Efficiency Brass Burners | Elegant Design | 2-Year Warranty

Elica Hob 4 Burner Auto Ignition Glass Top – 3 Mini Triple Ring Brass Burner and 1 Double Ring Brass Gas Stove (Flexi AB HCT 460)

Elica 75cm 4 Burner Auto Ignition Hob | CROWN FLEXI 475 LOTUS IND HD BRASS | SABAF Triple Ring Brass Burners | 8mm Toughened Glass | Windshield…

Elica 90cm 4 Burner Auto Ignition Hob | CROWN FLEXI 491 LOTUS IND HD BRASS | SABAF Triple Ring Brass Burners | 8mm Toughened Glass | Windshield…

Elica 60cm 4 Burner Auto Ignition Hob | RG FLEXI 460 LOTUS IND HD BRASS | SABAF Brass Burners | Built-in & Freestanding | Toughened Black Glass |…

Elica 90cm 4 Burner Auto Ignition Hob | RG FLEXI 491 LOTUS IND HD Brass | SABAF Brass Burners | Built-in & Freestanding | Toughened Black Glass |…

Elica 90cm 4 Burner Gas Stove | MATT TKN 904 CT VETRO BK | Matt Finish Toughened Glass | Heavy-Duty Forged Brass Burners | Round Metallic Knobs |…